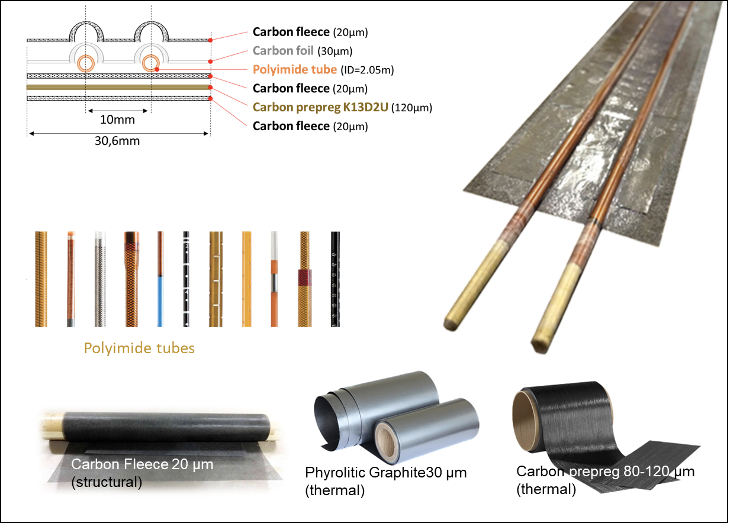

Ultralight Cold Plate (UCP) can be used for the cooling of power dissipating elements, based on micro-macro vascular pipes embedded in high thermal conductive carbon substrate.

The UCP was developed for sensors/chips thermal management of the new Inner Tracking System (ITS) that has been installed in the ALICE experiment at CERN in 2022.

UCP can have applications in drug production and other areas with need for cryogenics expertise.

Explore the technology specifics:

The CERN technology consists in an Ultralight Cold Plate (UCP) for the cooling of power dissipating elements, based on micro-macro vascular pipes embedded in high thermal conductive carbon substrate.

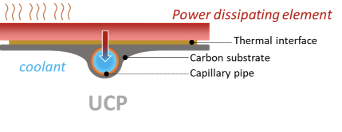

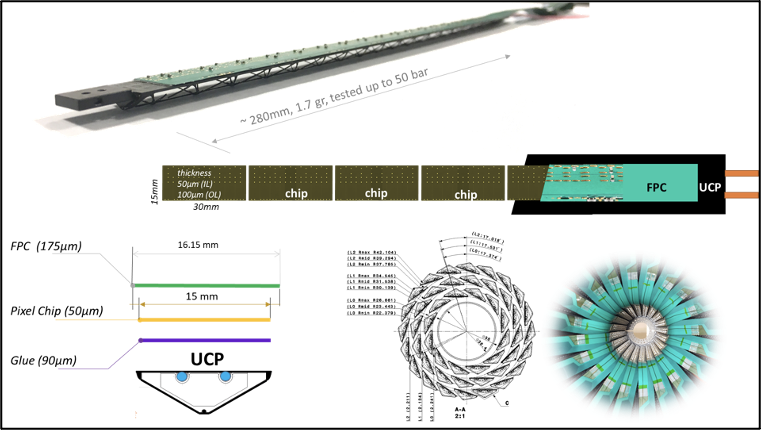

The UCP is made of a high thermal conductivity carbon plate, embedding ultralight polyimide cooling pipes. Different carbon materials are laid-up in the plate thickness to enhance thermal performance and guarantee structure integrity. The dissipating elements that need to be cooled down are in thermal contact with the UCP through glue or thermal interface materials. The heat is transferred from the dissipating elements into the cooling pipes by the carbon substrate and is removed by the coolant flowing in the pipes. Several coolants have been used, from single phase liquid (water) to two-phase evaporative (C4F10), and different ones are being tested (CO2).

- The technology has been fully developed at CERN, within the ALICE collaboration. UCP serial production (>300 units) was based at CERN in the ALICE Composite laboratory.

- The UCP was developed for sensors/chips thermal management of the new ALICE Inner Tracking System (ITS) that has been installed in ALICE in 2022. The ALICE ITS is a 12.5 Giga-Pixel camera consisting of seven cylindrical detection layers equipped with monolithic pixel sensors that covers a ~10m2 surface and dissipate about 400W/m2. The UCP for the ITS covers a length of 28cm for the three innermost vertex layers and up to 1.5 meter for the 4 outermost tracker layers. The UCP design had to comply not only with large heat removal capacity but also with the ALICE ITS tight requirements in term of extremely low material budget and radiation hardness. The UCP design has been adopted in another detector in ALICE, the Muon Forward Tracker. In addition, three other HEP Experiments have used the same UCP: NA61, MDP NICA and SPhenix.

The technology is unique because of its ofering.

- No similar technologies are present in the market.

- The UCP offers unique cooling performance and minimum material thickness and weight. The use of an optimised carbon plies lay-up combined with non-metallic tubes running in between the plies is a completely novel feature. The UCP are produced using a non-conventional manufacturing process for composite material tailored to this specific application. Several tests have been performed to optimise the lay-up of the different carbon plies and the embedding of the polyimide pipes, for the construction of the Cold Plate. Unidirectional High Thermal Conductive (HTC) carbon prepreg (pre-polymerised), pyrolytic graphite foil (PGF) and quasi-isotropic structural carbon lamina (Carbon fleece) are laid up in a double mould that allows at the same time the embedding of the polyimide pipes. After the manual lay-up of the different components, the UCP undergoes a curing process, based on heating and pressure cycles, required for the resin polymerisation and consolidation. Co-curing of carbon laminates and embedded pipes permits to optimise their thermal interfaces by minimising the amount of glue.

- The resin system for the CFRP is cyanate ester resin, which is preferable to epoxy resin for its low humidity absorption and better dimensional stability in time. The choice of the material for the cooling pipes embedded in the structure is driven by the requirement of low material budget, high thermal conductivity, and radiation hardness. A suitable compromise among these requirements is the use of a plastic tube with a very thin wall. Polyimide shows high radiation hardness up to at least 107 Gy and high radiation length, X0 ≈ 28cm. Small diameter pipes with 1.024mm (2.67mm) inner diameter and 25µm (64µm) thin walls have been used in two of the present applications in HEP detectors. A record ultralight cold plate weighing only 1.7 gram to cover a surface of ~280mmx15mm has been achieved including polyimide pipes of 1mm diameter and a structural stiffener also in carbon fibre for mechanical support.

- In the UCP the pipes are always embedded in the carbon structure and never directly exposed. In this way their intrinsic fragility and tendency to pinch and buckle under localised load does not affect their use. The connection to feeding lines is through a glued joint between polyimide pipes and fittings. The behaviour of the pipes and fittings was qualified under high pressure loads and polyimide erosion due to coolant (water) flow in radiation environment has been assessed. The polyimide pipes are commercially available on the market with a large variety of features and with an extremely tight quality control, being these pipes used in the medical field for vascular catheters. Different pipe sizes down to 50 micron in diameter and 6 micron wall are available on the shelf, as well local braided and coiled reinforcement for bending torsion and pressure increased performances; or specific laser machined features for OD reduction and connectivity. This large range of pipe properties open the possibility of further developments of the UCP technology, towards micro pipes (ID < 1mm) from one side and large surface coverage ( > 1.5m) on the other side, while both these R&D lines are being pursued at CERN.

The technology can have many applications in:

- High-energy physics

- Cryogenics

- Drug production

Reading material and records:

- Technical paper_CGargiulo and Bell_ https://indico.cern.ch/event/810687/contributions/3452034/attachments/1877493/3092189/20190710_CGargiulo_Bell.pdf

- Technical upgrade re CLIC– ALICE_ITS_Upgrade_CGARGIULO- (Relevant info slide 4 onwards)_ https://indico.cern.ch/event/388177/contributions/1820532/attachments/775930/1064037/20150528_CLIC-ALICE_ITS_Upgrade_CGARGIULO.pdf

- https://iopscience.iop.org/article/10.1088/1748-0221/13/08/T08003

- https://cds.cern.ch/record/1625842/files/0954-3899_41_8_087002.pdf